Salt spray test - corrosion resistance of electrogalvanizing products

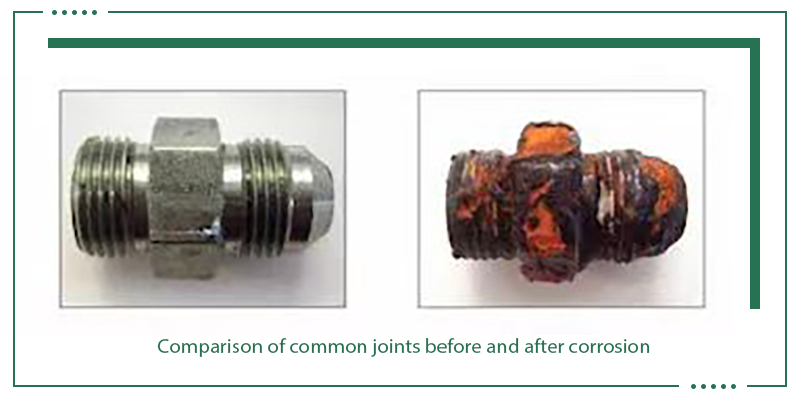

Corrosion is a key issue in extreme marine, mining, industrial and mobile applications, as well as many other markets, which can cause direct and indirect economic loss. In this regard, higher requirements are needed for the corrosion resistance of hydraulic joint fittings.

After more than 20 years of continuous exploration, trial, and development, the continuous iteration of mechanical production equipment update, DME greatly improved the standard corrosion resistance of hydraulic fittings. According to SAE standardized salt spray test, there will be no white rust in harsh environment for 168 hours and no red rust for 500 hours. Excellent.corrosion resistance can provide a safe and effective linkage solution for your hydraulic system.

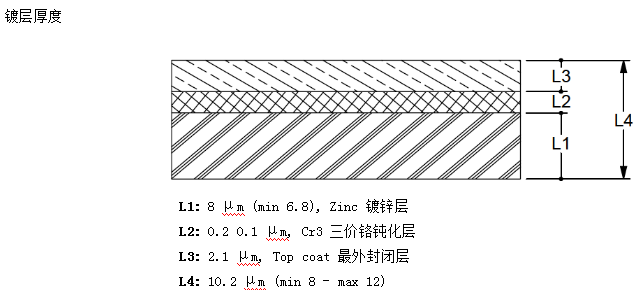

Cladding material parsing

1. Electrodeposited zinc coating with trivalent chromium white zinc treatment

2. Sealant sealing treatment

3. Total thickness :8-12 um

4. Smooth surface, fine grain, adhesion, no blisters, pits, or nodules

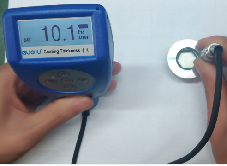

Test Report

|

DME锌层厚度检测报告The Test Report of Galvanized Layer Thickness |

||||||

|

表单编号 Form Number |

DMJX-JL-255 |

日期Date |

2022.03.03 |

|||

|

产品名称Product Name |

液压件 |

项目名称Project Name |

锌层厚度检测Galvanized Layer Thickness Testing |

|||

|

产品型号Product Model |

6409-10 |

项目编号Project Number |

20220303A106 |

|||

|

批次Batch Number |

21387 |

项目标准Project Standard |

PE-CONS 3627/00 |

|||

|

外观检查 Appearance Inspection |

划伤Scratch |

异物Foreign Matter |

色泽Lustre |

|||

|

N/A |

N/A |

OK |

||||

|

检查数量Sample Number |

① |

② |

③ |

|||

|

检测值:Test Value |

|

|

|

|||

|

平均值:Mean Value |

10.43 |

单位:Unit um |

||||

|

检测结论Test Conclusion |

合 格 Up to Standard |

|||||

|

制表Lister |

张琪 Zhang Qi |

检验员Inspector |

张琪 Zhang Qi |

审核Auditor |

刘勇 Liu Yong |

|

盐雾试验

|

DME盐雾试验报告 Salt Spray Test Report |

|||||

|

电话(TEL): 86-411-82490808 82490707 传真(FAX): 86-411-82483355 No.: DMJX-JL-256 |

|||||

|

Test Start Time测试开始时间:2022/05/01 Test End Time测试结束时间:2022/05/25 |

|||||

|

Test Sample Identification 测试样件 |

|||||

|

Sample Name 样件名称 |

Test ID No. |

Plating Type 镀锌类型 |

Supplier 生产商 |

Lot No 批次 |

|

|

Hydraulic adapter 液压接头 |

DAJCM907M-1212 |

三价铬白锌 trivalent chromium white zinc

|

DME |

22A201 |

|

|

Hydraulic adapter 液压接头 |

DABPM105M-0806 |

三价铬白锌 trivalent chromium white zinc

|

DME |

20126 |

|

|

Hydraulic adapter 液压接头 |

DAJCM106Q-0608 |

三价铬白锌 trivalent chromium white zinc

|

DME |

21158 |

|

|

Hydraulic adapter 液压接头 |

6400-0808 |

三价铬白锌 trivalent chromium white zinc

|

DME |

22036 |

|

|

Technical Requirement技术标准:: ISO 9227 NSS (GBT10125) |

|||||

|

White Corrosion |

白锈 ≧ 168 h (小时) |

||||

|

Base metai corrosion |

红锈 ≧ 500 h (小时) |

||||

|

设备Equipment: 盐雾试验测试机/(NSS)主要测试条件 Salt spray test machine /(NSS) main test conditions |

|||||

|

日期 |

试验箱温度 |

饱和器温度 |

沉降量 |

酸碱度 |

结果 |

|

Date |

Inside Temperat |

Satura tor |

Sedimentation Constant (ml/h) |

PH Value |

Result |

|

2022/5/1 |

35.2℃ |

37℃ |

1.2ml/h |

PH7 |

无腐蚀corrosion |

|

2022/5/2 |

35.1℃ |

37℃ |

1.2ml/h |

PH7 |

无腐蚀corrosion |

|

2022/5/3 |

35.2℃ |

37℃ |

1.2ml/h |

PH7 |

无腐蚀corrosion |

|

2022/5/4 |

35.1℃ |

37℃ |

1.1ml/h |

PH7 |

无腐蚀corrosion |

|

2022/5/5 |

35.0℃ |

37℃ |

1.4ml/h |

PH7 |

无腐蚀corrosion |

|

2022/5/6 |

35.1℃ |

37℃ |

1.3ml/h |

PH7 |

无腐蚀corrosion |

|

2022/5/7 |

34.9℃ |

37℃ |

1.2ml/h |

PH7 |

无腐蚀corrosion |

|

2022/5/8 |

34.9℃ |

37℃ |

1.2ml/h |

PH7 |

无腐蚀corrosion |

|

2022/5/9 |

35.1℃ |

37℃ |

1.1ml/h |

PH7 |

无腐蚀corrosion |

|

2022/5/10 |

35.0℃ |

37℃ |

1.4ml/h |

PH7 |

黑斑black spot

|

|

2022/5/11 |

35.1℃ |

37℃ |

1.3ml/h |

PH7 |

黑斑black spot

|

|

2022/5/12 |

34.9℃ |

37℃ |

1.2ml/h |

PH7 |

黑斑black spot

|

|

2022/5/13 |

34.9℃ |

37℃ |

1.2ml/h |

PH7 |

黑斑black spot

|

|

2022/5/14 |

35.1℃ |

37℃ |

1.2ml/h |

PH7 |

黑斑black spot

|

|

2022/5/15 |

35.2℃ |

37℃ |

1.2ml/h |

PH7 |

白锈 white rust |

|

2022/5/16 |

35.1℃ |

37℃ |

1.1ml/h |

PH7 |

白锈 white rust |

|

2022/5/17 |

35.0℃ |

37℃ |

1.4ml/h |

PH7 |

白锈 white rust |

|

2022/5/18 |

35.1℃ |

37℃ |

1.3ml/h |

PH7 |

白锈 white rust |

|

2022/5/19 |

34.9℃ |

37℃ |

1.2ml/h |

PH7 |

白锈 white rust |

|

2022/5/20 |

34.9℃ |

37℃ |

1.2ml/h |

PH7 |

白锈 white rust |

|

2022/5/21 |

35.1℃ |

37℃ |

1.2ml/h |

PH7 |

白锈 white rust |

|

2022/5/22 |

35.0℃ |

37℃ |

1.1ml/h |

PH7 |

白锈 white rust |

|

2022/5/23 |

35.1℃ |

37℃ |

1.4ml/h |

PH7 |

白锈 white rust |

|

2022/5/24 |

34.9℃ |

37℃ |

1.3ml/h |

PH7 |

白锈 white rust |

|

2022/5/25 |

35.2℃ |

37℃ |

1.2ml/h |

PH7 |

红锈 red rust |

|

试验图片说明Test picture description |

||||||

|

|

DAJCM907M- 1212 |

DABPM105M-0806 |

DAJCM106Q-0608 |

6400-0808 |

备注 remarks |

|

|

240h |

|

|

|

|

黑斑 black spot |

|

|

360h |

|

|

|

|

白锈 white rust

|

|

|

600h |

|

|

|

|

红锈 red rust |

|

|

结论Conclusion:: |

合格 Qualified |

|||||

|

操作员Operator: 冯利军 Feng Lijun |

审核Reviewed by: 刘 勇 Liu Yong |

|||||

版权所有:1993~2026 大连笛美机械工业有限公司(DME)

电话:+86-411-82490707, +86-411-82490808 传真:+86-411-82483355 技术支持:奈特原动力